Italian, niche and quality products are the common features of R.G.V. and REBER, which decided to join and support each other to growth together

A very interesting project was born from the union of two companies of the niche small appliance for the kitchen: REBER, a professional of products for food transformation and conservation, and RGV, specialized in slicers and other semi-professional and professional kitchen appliances. Two very similar realities for vocation, niche product sectors, high quality production and, of course, both proud ambassadors of Made-in-Italy.

With a medium-long term development plan, well thought out, they have decided to combine skills and synergies to support mutual growth in Italy and abroad, while keeping alive their identity and individuality. After a preliminary exchange of shares, the two companies will keep their respective brands separate, assessing together possible future opportunities in the various production, commercial and distribution sectors, in order to be able to respond promptly to the demands of a changing and versatile market.

The common focus of R.G.V. and REBER remains the offer of an Italian product, professional or professionally inspired but suited to domestic needs, and addressed both to the customers of the Peninsula and to foreign ones, among which both brands are already known and very appreciated. To tell the birth and the premises of this union, are Maurizio Re, owner of REBER and Marco di Leo, managing director and commercial director of R.G.V.

How did the merging of your two companies take place?

Marco di Leo: This is not actually a merger, but a plan according which at the moment we exchanged companies shares with a project, from now to 5 years, of creating a single identity. Maurizio Re: The idea is to start slowly, trying to collaborate and to integrate progressively, first on a commercial and then on a production level, to arrive at the end of the path to the merger of the two companies.

What reasons led to this operation?

M.d.L.: The reasons are several: from the fact that we think that being two is better than staying alone, to the fact that the protagonists of the two companies are very similar, with the same origin, both hard workers. Furthermore, two Made-in-Italy production companies like ours can develop different synergies, both on a commercial and a production level.

M.R.: The main reason that led REBER towards the search for an industrial partner lies in the awareness that to face increasingly complex markets it is essential to grow, to be more competitive and to have more opportunities to invest in new products and foreign markets.

What do REBER and R.G.V. have in common and in what are they complementary?

M.d.L.: The two companies have in common Made-in-Italy and the fact of realizing a niche product: slicers as regards R.G.V. and vacuum machines, bags and mincers, as regards REBER. The two market segments are therefore strongly complementary.

M.R.: The common aspects are the will to be and remain strongly characterized as companies of Italian production. Furthermore, we share the fact that we are specialists in niche products. The complementarity is obviously that of the two catalogs of products, which integrate and combine perfectly.

Has the merger already been completed or have you planned various steps to be taken to close it?

M.d.L.: The merger is not completed, there will first be an exchange of companies shares to come then to a common project, from here to the next five years, with various steps, to become a single entity.

M.R.: The process started with a commercial collaboration and an exchange of company shares; the project then follows a path of (at least) five years, to increase more and more the level of integration and to achieve a real merger.

What is the strategy of the new reality you have set up?

M.d.L.: The strategies are those that drove us to realize this union, starting from the production and commercial strategies themselves. At the moment, the two companies are flourishing and will continue to work independently… So…the less you change, the better is.

In the long term there are common projects and strategies that for now we do not want to “unveil ” in detail.

M.R.: The fixed point, at the start, is not to touch what works, and so to continue on the ways already set independently by REBER and R.G.V.; initially we will evaluate the opportunities that will arise on individual markets or specific customers/products, then calmly we will start to follow common strategies and develop products together.

How are you organized at operational level? Are there divisions that will merge or will you keep two separate managements?

M.d.L.: Currently there are 2 distinct brands and both will be maintained; for now the management will be autonomous and independent of each other.

M.R.: Both companies have their own brands and their own identity on the market, which will continue their journey independently and autonomously. Along the way we will assess the opportunities for process rationalization.

So will your brands continue to coexist? Will they also maintain the same position they had before or will it change?

M.d.L.: Yes, our brands will continue to coexist. If they are going to maintain the same positioning it is too early to say, let’s see how the market will develop over time. Moreover we speak of a constantly evolving market to which we must adapt and react immediately.

M.R.: Surely the brands will remain and the will is to continue to keep them characterized as they have been up to now, this does not mean that the needs of the market may require future developments, which at the moment we cannot predict.

How is the offer of the new REBER-R.G.V. reality composed: which product segments are part of it and which channels are they intended for?

M.d.L.: At the time R.G.V. is directed to the organized distribution, while REBER to the homeware and hardware stores. Both companies make semi-professional and professional products (so an additional market segment). The channels to which the two companies, together, will be destined, can be understood only over time, adapting to the needs of the market.

M.R.: To date, the “vocation” of the brands is fairly clear; organized distribution for R.G.V., distribution in the homeware and hardware sectors for REBER. The products are addressed to semi-professional users and the idea is to continue the “vertical” development of the product lines, to go to touch ever larger segments of potential customers, from the domestic/casual user to the professional one.

Will you develop a new distribution policy?

M.d.L.: Why not? At the moment each will go on with its distribution policy, then we will see what strategies to adopt and how to combine our actions to achieve a more capillary and targeted distribution .

M.R.: For now it was not discussed, but the issues that the market submit us are certainly easier to deal with if we have several brands and different production realities available, which can meet different needs. If in the past we had to limit our “range of action”, the synergies that this collaboration offers us could allow us to face more demanding challenges with greater serenity.

Are you planning a communication plan to transmit the potential of your union?

M.d.L.: Not at the moment. A communication plan does not change big things. Instead, it will be necessary to work seriously and show that we have made the right choice.

M.R.: Before worrying about a communication plan, given the history of both companies, I think it’s more important to work on the contents that we go to propose to the market, and then on how to communicate them.

Will it change anything in your international strategy?

M.d.L.: In terms of international strategy, something has already changed because we have combined our energies and we have already participated in some trade fair together, with a single booth, but always displaying both the brands and the two production companies.

M.R.: International markets are undoubtedly the most important and promising aspect of this collaboration, and in fact we have already begun to participate together to some international events; here the individual countries will have to be evaluated and the offers of the two companies integrated, it will take time to get to the regime, but there are very interesting growth spaces.

What are the main markets in which you are currently exporting?

M.d.L.: R.G.V. exports mainly to Europe, in almost all States; then, to a lesser extent, also in South America, United States, South Africa and Australia.

M.R.: Reber has its main market in France after Italy, but it is also present throughout Europe, the United States and Canada, Australia, South Africa and India.

How does the demand for products in your sector change in the various countries in which you are present?

M.d.L.: It varies a lot: abroad R.G.V. products enter in the professional sector, for insiders, so theoretically they could go anywhere.

There are clearly developing countries where there is not yet a culture for professional equipment in general. The two companies are essentially single-product and their complementary production could certainly open the door to new markets that, taken individually, would not give the same result.

M.R.: Proposing products for food processing and storage, demand is influenced by the food habits of the various countries; the most promising sector is undoubtedly that of professional equipment, which potentially opens us the doors around the world, but working on market niches we can find outlets also in private use, and the fact of putting together different “niche” products makes us more interesting at the eyes of the potential distributor.

What expectations do foreign customers have regarding the Italian product?

M.d.L.: The expectations for the Made-in-Italy product are always high; the product is highly appreciated but must also be performant, with an attractive design as well as having an excellent price-quality ratio.

After China has raised prices a bit, there seems to be a return to Made-in-Italy.

M.R.: Made-in-Italy has always a great appeal in the world, in particular concerning cooking and food; in addition to the performance and quality of the product today, even in the professional sector, aesthetics plays a decisive role, but the quality of Italian production is still a business card that can be spent in the eyes of the international buyer.

What targets do you have for the future of your new organization?

M.d.L.: Surely expectations are high; we will do our best to optimize our synergies.

M.R.: The expectations are certainly ambitious, because the potential we have seen in creating this collaboration seemed to us absolutely significant. Now we must work hard to make them happen, but due to the nature of both companies, we are not interested in immediate but ephemeral results, our goal is an important growth, but healthy and lasting over time.

| R.G.V., THE PROFESSIONAL EXPERIENCE ARRIVES AT HOME With over thirty years of experience behind it, R.G.V., located in Cermenate (CO), is famous for its professional slicers, also made in domestic version. Despite maintaining the core business in this segment, from its origins to today, the company has ranged across various product categories, including other types of items in its catalog, from restaurant equipment to small appliances. The great technical-engineering skill of the company allows many innovations to be transferred from the professional sector to the domestic ranges, which today stand out for the high performance and quality of the proposed references. In addition to many slicer models, R.G.V. also offers steakers/contact grills, induction cooking, toasters, dehydrator, citrus-fruit squeezer, juice extractors and further products. |

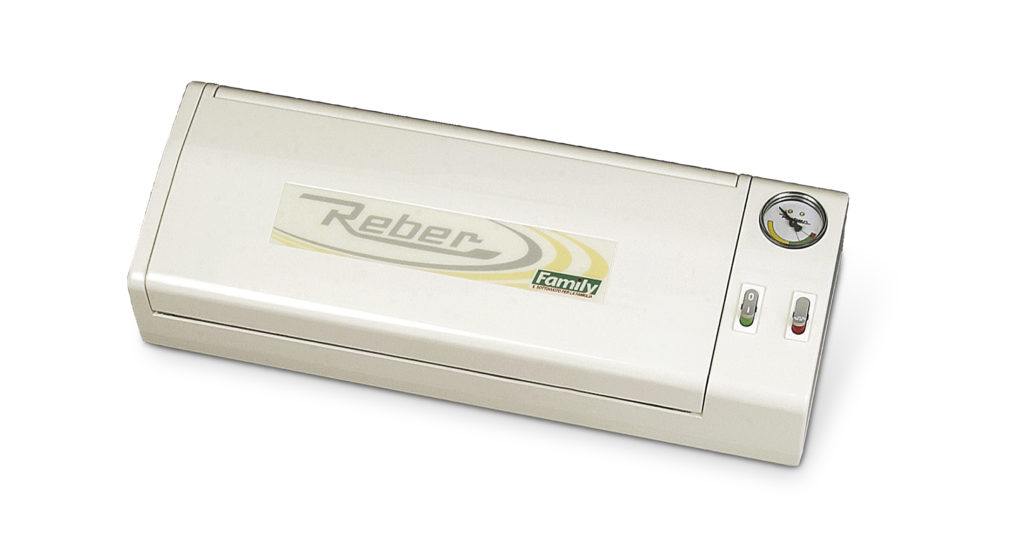

| REBER, PASSION FOR QUALITY REBER was born in Luzzara, in the province of Reggio Emilia, in 1964. It starts as a mechanical processing company for third parties and then devoted itself to the production of small appliances with more and more professional quality. Today REBER products are divided among professional, semi-professional and domestic articles, sharing solidity, high performance and attractive and ergonomic design. Among the leading products of the domestic line, we can mention vacuum machines, electric tomato machines, meat mincers, slicers and graters. The company's experience in the professional field has made it possible to make available very particular appliances to domestic users, such as sausage fillers and smokers. Transmitting passion for innovation and efficiency is the mission of the brand, now present both in Italy and in several foreign countries. Since 2011, the operational headquarters have been transferred to Correggioverde (MN). |